Temperature Monitoring Made Simple

Eliminate manual checks, simplify compliance logging, and reduce the risk of product loss with our easy-to-deploy automated temperature monitoring solution.

Get Started

Easily Manage Product Safety & Compliance

Keep the temperature of cold storage equipment at optimal levels

to ensure product quality and safety, and eliminate loss.

Grocery & Convenience Stores

Enhance food shelf-life, minimize waste, and eliminate the process of manually checking and recording fridge and freezer temperatures.

Food Service

Preserve food quality, reduce waste, and uphold food safety standards in hotels, restaurants, and catering.

Health Care

Ensure the integrity and safety of medical products, maintaining compliance and patient safety.

How Does it Work?

Discrete wireless sensors continuously monitor equipment temperature. The data is accessed in our web-based application and easily integrated with work order management systems.

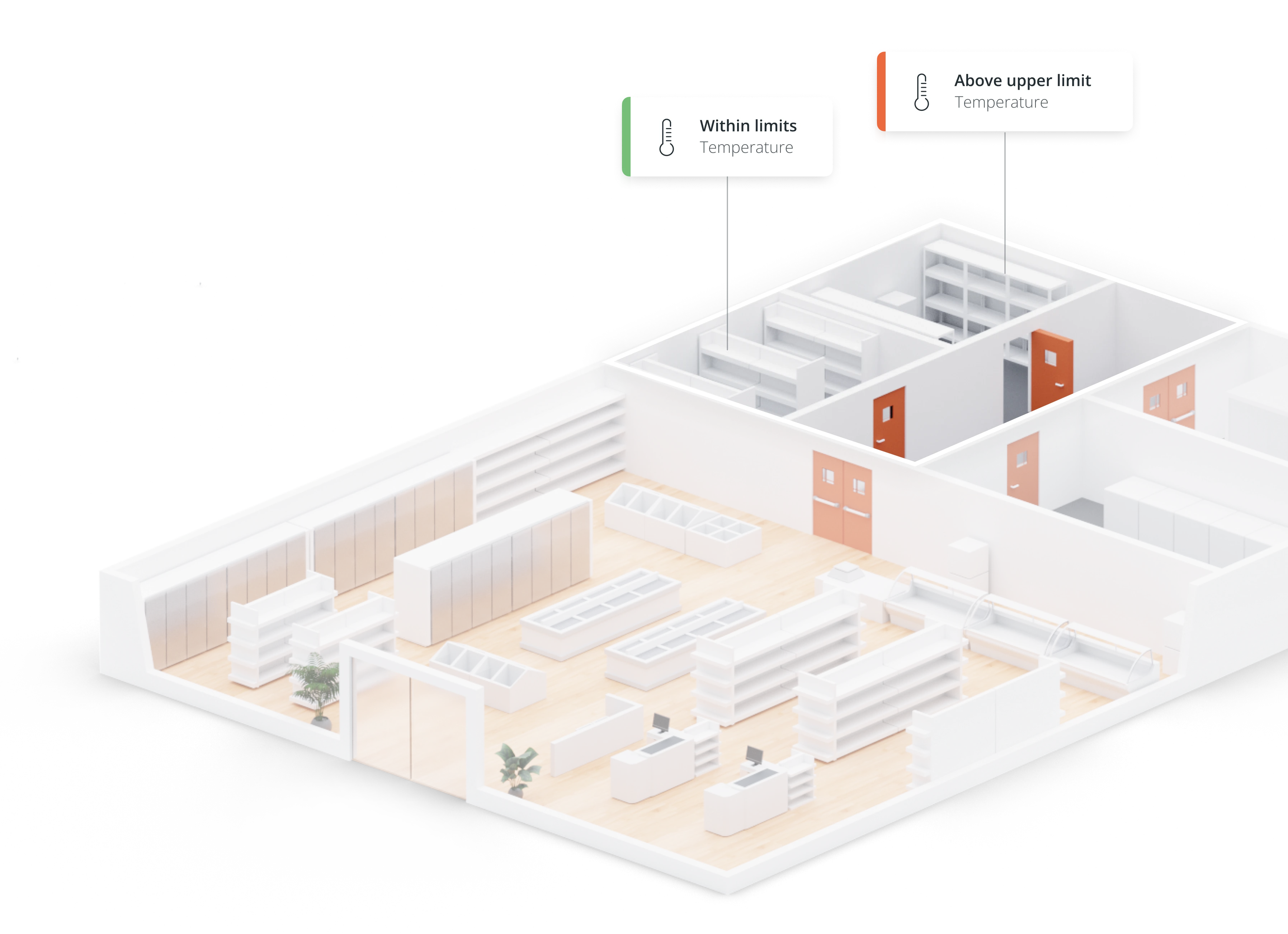

Continuous Temperature Monitoring of Cold Storage Equipment

Automatically monitor and log the temperature of fridges, freezers, and cold rooms.

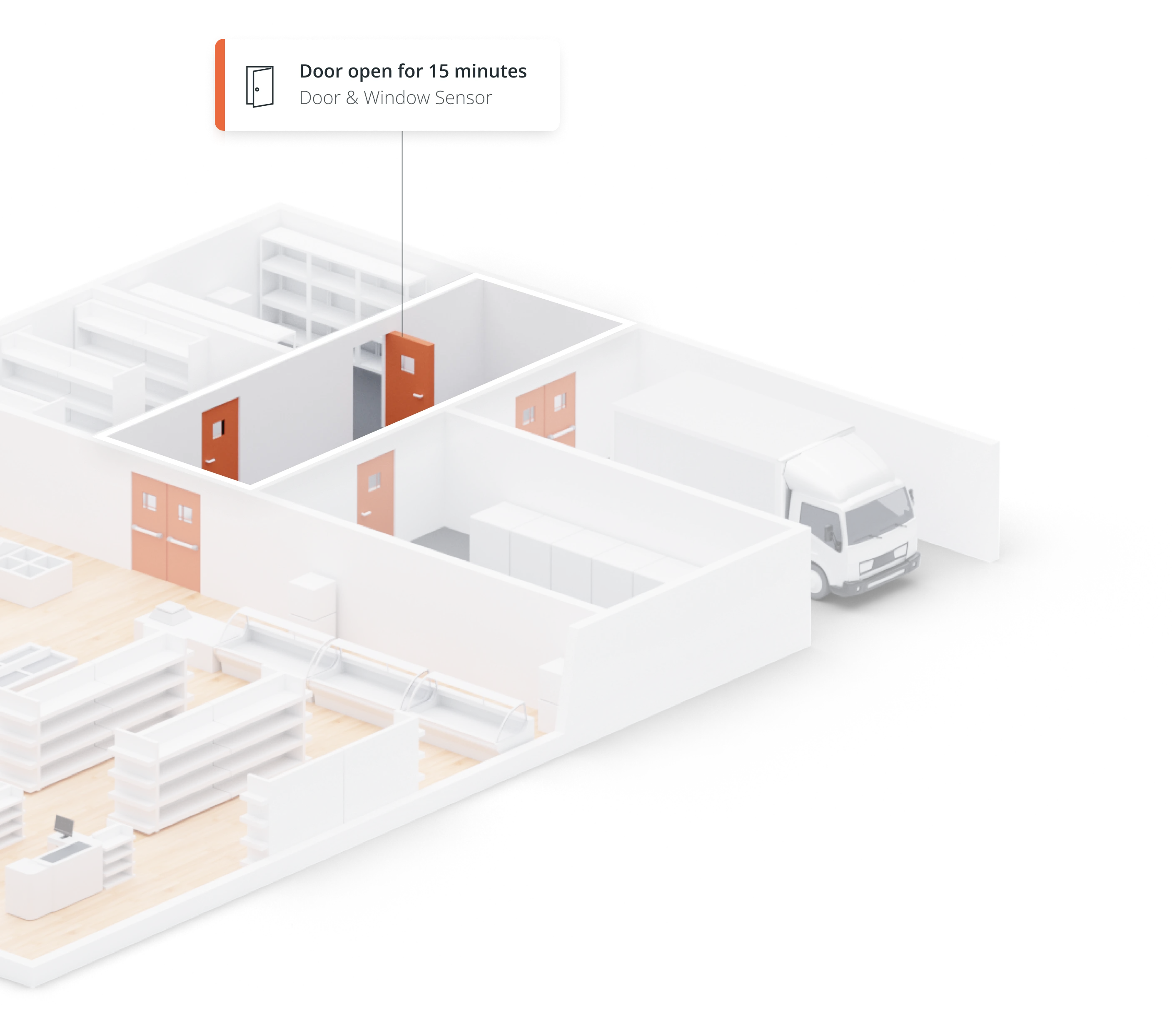

Fridge and Freezer Door Monitoring

Remotely monitor the door activity of fridges and freezers to understand whether they are open, closed, or ajar.

Instant Notifications

Receive an alert if the temperature deviates from a defined range to take timely action.

Analyze Insights

Easily analyze sensor data in

our web-application, Studio.

Integrate Sensor Data

Build a solution on top of our APIs or integrate data into your

existing cold chain management solution.

Unlike Any Other Temperature Monitoring Solution

Our solution makes it easy to remotely monitor temperature, ensuring a hassle-free experience from easy installation to dependable data.

Easy to deploy

Other solutions may require wiring, screws for mounting, and gateway pairing, significantly increasing installation effort. Bulky hardware is exposed to damage and may get in the way of product placement.

Peel-and-stick sensors adhere to any surface, communicating wirelessly without setup or pairing. Simply plug in the gateway to begin data collection. This streamlined approach significantly reduces the cost and effort of installation.

Reliable data

If a system goes down during a power outage, data from that time will be lost. False alarms, caused by normal temperature rises distract personnel and make it more likely that the message will be ignored in the case of a real issue.

If the connection to the cloud is lost, our sensors can store up to 100,000 data records offline for full data access. To avoid nuisance alerts, a built-in buffer ensures that personnel receive notifications only when the products inside are at risk.

No maintenance over 15 years

Sensors that are not designed specifically for cold storage environments are often damaged by ice or water or because they are knocked out of place. Regular battery changes quickly add up in terms of time and expense.

Low temperatures can reduce battery life. Our sensors capture data for up to 15 years at temperatures down to -200°C / -328°F. IP68-rated design protects the sensors from damage or displacement, eliminating maintenance entirely.

Do You Have a Cold Chain Management Solution?

We team up with industry-leading partners to create solutions that bring even more insight and automation to end user operations

The Beginner's Guide to The Internet of Things

Get Started

.png)

.png)